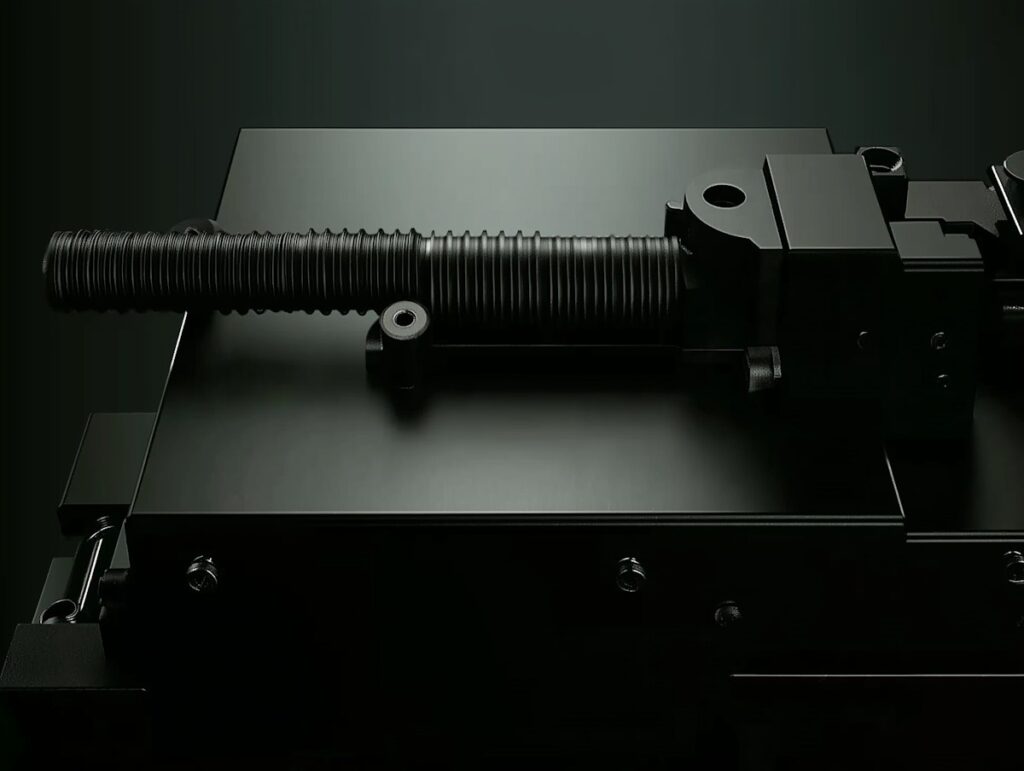

At ExCom, we specialize in fabricating functional 3D-printed parts that solve real problems. Whether it’s replacing discontinued components, fixing broken tools, or designing organizers for commercial spaces, our process helps restore or enhance what’s already working — or bring something entirely new to life. Most projects start as custom one-offs, but many evolve into small production runs once we identify broader demand.

We reverse-engineer broken or out-of-production parts, especially for vintage vehicles, tools, and specialty equipment. From flexible, heat-resistant materials to outdoor-ready plastics, we select the right blend for your use case. And if you don’t have a CAD file or exact model? No problem — we can help redesign the part to function even better than the original. Whether it’s for a restaurant, workshop, retail space, or product team, we deliver reliable, fit-for-purpose solutions—fast.

At ExCom, we specialize in fabricating functional 3D-printed parts that solve real problems. Whether it’s replacing discontinued components, fixing broken tools, or designing organizers for commercial spaces, our process helps restore or enhance what’s already working — or bring something entirely new to life. Most projects start as custom one-offs, but many evolve into small production runs once we identify broader demand.

We reverse-engineer broken or out-of-production parts, especially for vintage vehicles, tools, and specialty equipment. From flexible, heat-resistant materials to outdoor-ready plastics, we select the right blend for your use case. And if you don’t have a CAD file or exact model? No problem — we can help redesign the part to function even better than the original. Whether it’s for a restaurant, workshop, retail space, or product team, we deliver reliable, fit-for-purpose solutions—fast.